Vaporized Hydrogen Paraoxide Pass Box (VHP Pass Box)

Product Details:

Vaporized Hydrogen Paraoxide Pass Box (VHP Pass Box) Price And Quantity

- 250000.00 - 400000.00 INR/Number

- 1 Number

- 250000 INR/Number

Product Description

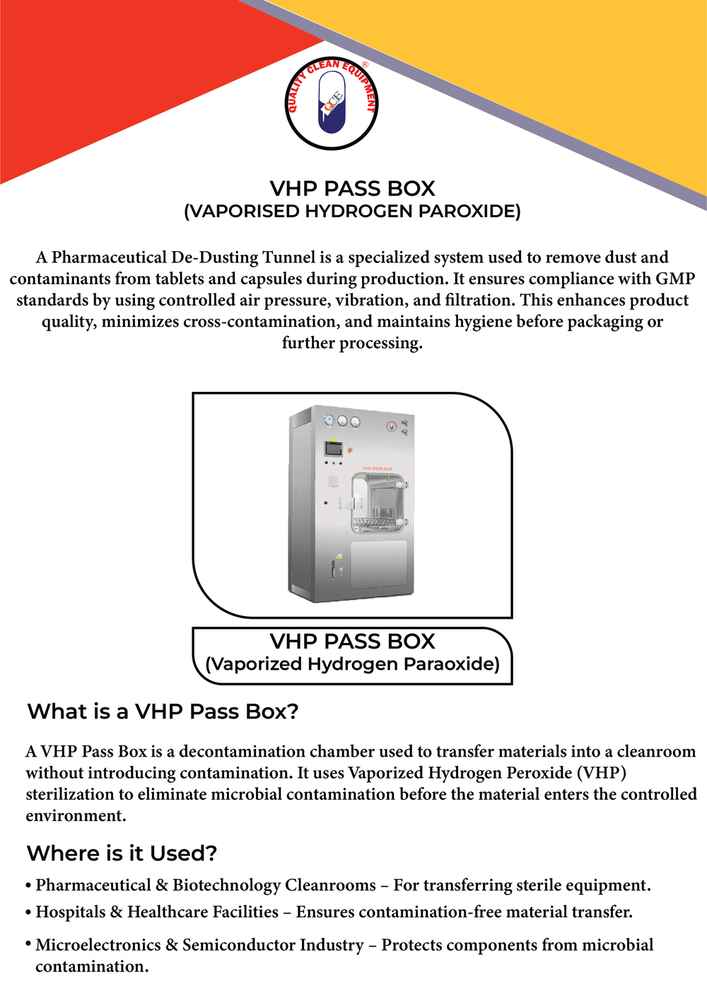

What is a VHP Pass Box?

A VHP Pass Box is a decontamination chamber used to transfer materials into a cleanroom

without introducing contamination. It uses Vaporized Hydrogen Peroxide (VHP)

sterilization to eliminate microbial contamination before the material enters the controlled

environment.

- Pharmaceutical & Biotechnology Cleanrooms “ For transferring sterile equipment.

-

- Hospitals & Healthcare Facilities “ Ensures contamination-free material transfer.

-

- Microelectronics & Semiconductor Industry “ Protects components from microbial

Integrated Bio-decontamination System

Esco Pharma has developed an effective hydrogen peroxide based bio-decontamination

system capable of achieving a log 6 reduction in bio-burden. The spore log reduction has

been validated by biological indicator challenge using biological indicator stainless steel

ribbons populated with Geobacillus Stearothermophilus spores.

Integrated Bio-decontamination System

The interior and cleanroom side face is made of 316 L stainless steel with a smooth

interior and coved corners to ensure easy cleaning and biodecontamination.The interior

surface is polished to 0.6 Ra m or better and external surfaces exposed to cleanrooms

1.2 Ra m or better. The cleanroom wall interface allows a flush finish with the

surface for cleanliness.

Chamber doors are constructed from FDA compliant materials with integrated FDA

approved silicone inflatable seal around the perimeter. Doors shall give >90 opening for

full access. The doors are not held closed with a mechanical latch, they are the same as

our isolators where the seal locks them closed.

Direct reading pressure gauges are provided to both sides of the pass through to give

indication of the chamber pressure.

Integrated with Esco BioVAP bio-decontamination system with PLC control, HMI

operator interface and ticket roll printer to give hard copy of the

bio-decontamination cycle.

Interlocking doors to prevent opening at the same time and also to prevent the sterile

unloading doors from opening until after a bio-decontamination.

exhausted back to room, with interlocked safety exhaust H2O2 sensor. Avoids costly

HVAC ducting.

How Does It Work?

Material is placed inside the VHP Pass Box.

The doors interlock to prevent direct exposure.

The system injects and circulates VHP gas inside the chamber.

Hydrogen peroxide sterilizes all surfaces, killing 99.99% of microorganisms.

After sterilization, the gas is neutralized, and the material is ready for transfer.

Specifications

Material: SS 304 / SS 316L construction.

Decontamination System: VHP-based sterilization.

Filtration System: HEPA filters (99.99% efficiency).

Door System: Electromagnetic interlocking doors.

Control Panel: PLC-based touchscreen with sterilization cycle settings.

Features

100% Sterilization “ Destroys bacteria, viruses, fungi & spores.

No Residue, No Damage “ Safe for pharmaceutical & electronic materials.

Fully Automated Process “ Ensures consistent sterilization cycles.

Safety Mechanism “ Door remains locked until complete sterilization.

Energy Efficient “ Low power consumption with optimized VHP usage.

Compliance & Standards

cGMP

ISO 14644

WHO-GMP

FDA

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS